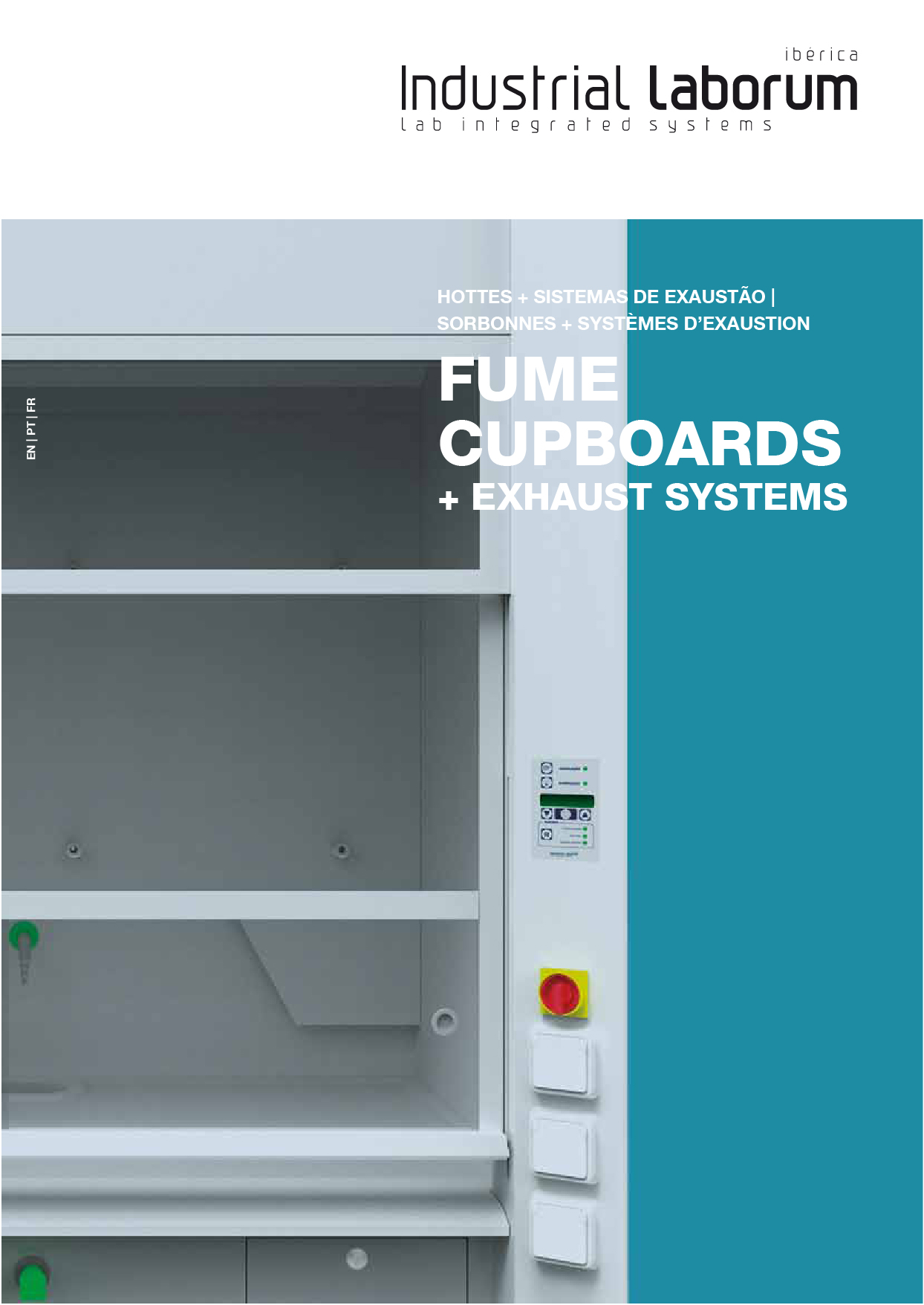

ENS Fume hood

The Indlab ENS fume hood integrates one of the 11 models of fume hoods from Industrial Laborum Ibérica and is the ideal fume hood for handling hazardous products that require high operating reliability of the equipment, with a lower investment.

The ideal fume hood for testing hazardous products that require high operating reliability.

Through a laminar flow inside the work cabin, this fume hood avoids turbulence and the possibility of escaping gases that pose a danger to users of the fume hood and the laboratory in question, thus allowing handling and carrying out tests with dangerous products.

The ENS Fume hood was developed in accordance with the standards IN 14175-2: 2003 e IN 14175-3: 2003.

- IN 14175-1: 2003

- IN 14175-2: 2003

- IN 14175-3: 2003

- EN 13150: 2001

- IN 61010-1: 2001

- IN 61326-1: 2006

Appointment CE according to the directives: 2014/30 / EU (Electromagnetic compatibility) and 2014/35 / EU (low tension).

Adaptation to the USA market

ENSUS

To ensure that this fume hood was adapted to the US market, Industrial Laborum Ibérica developed a fume hood in accordance with the USA Regulation – Services in the fume hood's side towers.

Greater simplicity and more economical

ENS Fume hood was developed to facilitate its handling, allowing greater attention to the products in use, given their dangerous nature. This is due to the controls and sockets being present on the fume hood's front panel. Its simplicity gives this model a very attractive value.

The ENS Fume hood model features 2/3 schuko-type sockets (type F), a cold water valve and a gas valve, as well as a fixed drip cup on the work surface.

IndLab Fume Hood has a constant air volume (VAC) system but sometimes it is necessary for the air volume to be variable, in which case a VAC system (variable air volume) can be installed, which contributes to an optimization of the energy consumption of the fume hood.

At Industrial Laborum Ibérica we produce products adapted to our customers, hence we present different types of materials that adapt to their needs.

IndLab ENS Fume hood has different materials for the different components:

— Outer structure: steel plate;

— Interior Structure: polypropylene, ceramic stoneware, steel plate;

— Bench: Compact phenolic, ceramic stoneware or granite.

Depending on the type of products that will be handled in the fume hood, the following combinations are recommended:

Standard: Indlab ENS Fume hood Standard for general use of chemical material, with exterior in cold rolled sheet steel, interior and work surface in different materials. For a more intensive use of chemical materials, it is recommended that the interior and work surface be in ceramic stoneware, for better performance of the fume hood over time.

Acids: IndLab ENS Fume hood developed for acidic chemical materials, with exterior in cold rolled steel sheet, interior and work surface in polypropylene. It is a fume hood recommended for those who intend to work with strong acids and very corrosive materials, ensuring stability and safety for users. However, due to the nature of polypropylene, it is not advisable to use material or equipment with high temperatures, as they damage the polypropylene.

Radioisotope: Fume Hood specifically developed for radioisotope chemical materials, with stainless steel exterior, interior and work surface. It is a fume hood recommended for those who intend to work with a radioisotope, ensuring stability and safety for users. It is also a fume hood recommended for those who work in environments with high temperature and that need to be constantly cleaned, however, due to the nature of the material, it is not a fume hood recommended for working with some acids.

In the Indlab ENS Fume hood, the controls and electrical sockets are placed on the fume hood's front panels under the lid, and the spouts are provided inside the fume hood on the worktop or in panels on the sides of the inner casing. There is also the possibility of being supplied with controls and sockets on the side props.

In addition to being equipped with a VAV (variable air volume) system, in order to improve the performance of the fume hood and its energy consumption in general, the fume hood can also be equipped with an automatic window closing system, or with the collection system of SCAT chemical waste.

The fume hood installation site must have a magnetothermic circuit breaker to ensure that if there are other equipment connected to the differential switch, they are not without power supply in case the fume hood needs to be maintained.

We are available to get in touch with you, as we also develop different fume hoods from those mentioned above.

Industrial Laborum Ibérica is a company with 44 years of experience in the market, which seeks to bring the quality factor to all laboratories. Through customers in the most diverse areas, such as health, education and different industries, ILI has acquired know-how that allows it to create solutions for the needs or requests of its customers. We are here to develop labs for people.